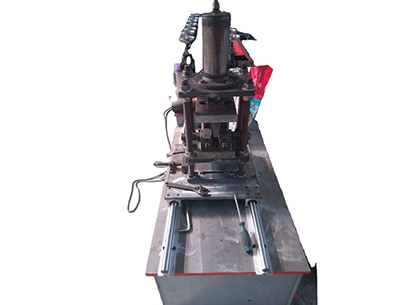

l shape metal ceiling grid wall angle tee roll forming machine with hydraulic cutter

false ceiling roll forming machine

Metal steel roof aluminium corrugated roller machine

![]()

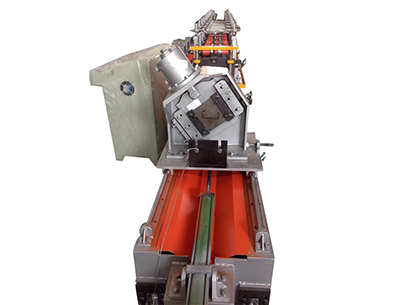

|

Feeding form |

Manual tightening, passive feeding |

|

Feeding rack load |

5T |

|

frame |

350H section steel welding |

|

Forming machine guide feed frame |

Side-skate peak distance |

|

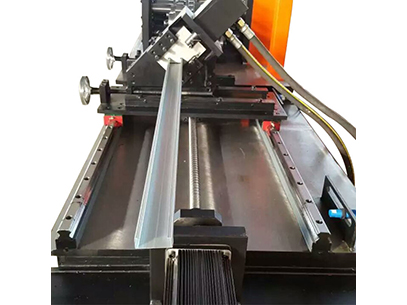

Forming machine form |

Wall plate chain drive |

|

Shaft diameter |

φ 70mm, solid shaft |

|

Chain |

1 inch single row |

|

Forming machine motor power |

5.5KW |

|

Forming speed |

8-10m / min |

|

Number of Rollers |

13 Row |

|

Roll material |

45 # steel forged parts |

|

Hydraulic station motor |

4kw |

|

Hydraulic station oil pump |

Gear pump |

|

Cut off method |

Hydraulic shear |

|

Forming scissors material |

Cr12 |

|

Shear blade heat treatment |

HRC58 ° -60 ° |

|

Rolling thickness |

0.3-0.8MM |

|

Material development width |

914mm |

|

Length sizing accuracy |

± 2mm |

|

Computer control |

PLC |

|

drive |

Servo motor drive |

![]()

Q: How to maintain the machine?

A: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

Q:How many workers to operate the machine?

A:Only 1-2 workers.

Q: How to visit your company?

A:a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

Q: What can you do if the machine broken?

A:Our machine’s warranty period is 12months,if the broken parts can’t be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

Q:How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) Please visit company and test machine if convenient.