Description

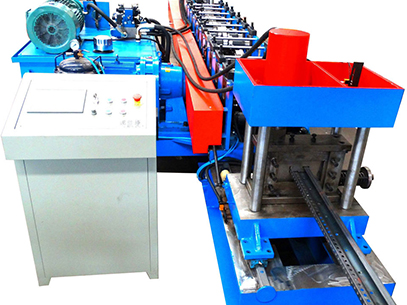

Electrical cabinet frame roll forming machine

Automaitc electric factory using cabinet frame roll forming machine with welding for electric cabinet rack, electronic box pole, metal case frame which using in switchgear system, low voltage panel building, control cabinetelectrical instruments etc.

I.Technical parameters (Item:YX42.5-42.5)

| No. | ITEM | PARAMETER | REMARK | |

| 1 | MATERIAL | Type | Cold-rolled strip steel, galvanized sheet | |

| T.(mm) | 1.5mm | |||

| Yield Strength (Mpa) | Q235 | |||

| 2 | Forming product Width | 42.5mm | ||

| 3 | Forming speed (m/min) | 2-6m | Including welding | |

| 4 | Forming main power (KW) | 11 KW*2 pcs | FYR | |

| 5 | Hydraulic power (KW) | 18.5 KW | FYR | |

| 6 | Voltage | AC380V,50Hz,3P | ||

Ⅱ, Electronic control panel frame production line process

(A) 2 in 1 Uncoiler Straightening→servo feeder→punch → Guide device → roll forming machine → Roller welding →shear device (including knife)→ finished product rack

Ⅲ, Roll Forming machine list

(1), 2 in 1 Uncoiler straightener

1,Type Manual Expansion

2,Parameter

1) Passive discharge

2) Coil weight:<3T

3) Coil inner D.:φ450mm-φ530mm

4) Max. Width.400mm

5) Thickness .0.4-1.6mm

6) Straightener roller :7 pcs

8) Power.1.5kw

(2),Servo Feeder

3.1 Max. feeding width 400mm

3.2 Feeding thickess 0.4-1.6mm

3. 3 Motor , 1.3KW(Yaskawa)

(3), Hydraulic hole punchin system/Punch machine

3.1 Function:Hydraulic punch hole (Mould 1 set)

3.2 Structure: set the length, automatic length measurement, automatic positioning reaches the set distance stop action , hydraulic cylinder driven punching die, stamping automatic shutdown.

3.3 Hydraulic system working pressure:16MPa

3.4 Hydraulic station:18.5KW( Hydraulic punch hole/shear use same station)

(4)Guide device

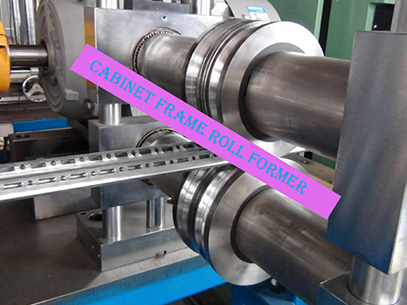

(5)Main Forming machines (for panel width mm )

5.1 Forming Roller:40 stations,and add Rub-roll, To make sure the surface profile no scratches.

5.2 Side Panel:T.25mm ,A3 steel Heavy duty .

5.3 Rolling speeding: 2-8 m/min.

5.4 Roller material:GCr15,overall quenching, hardness HRC56-62 ℃.

5.5 Motor power:11KW*2pcs.

5.6 Main Roller :φ75mm

5.7 Equipment base: 450 # H type using welded steel plate.

5.8 Transmission: chain drive.

5.9 Security: across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operator safety. And other gear in the chain and the staff could easily lead to injury transmission section covered with protective cover, to ensure the safety of workers.

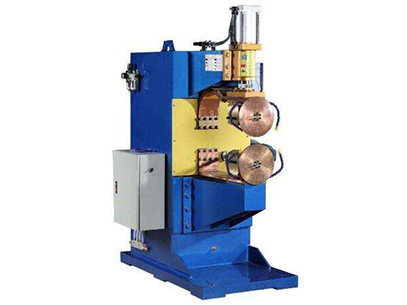

(6)Roll welder (Seam welder) in roll forming line

(7),Flat collect rack

(8),Electrical control system

The entire line imported PLC control, LCD touch screen, man-machine interface. People interact with the PLC. Operator setting the program to run automatically (programmable control) and control process monitoring, production line operator control and modify the control parameters, and real-time monitoring the equipment status & parameters and fault indication. Workpiece length digital setting, adjustable length can be adjustable as well. Real-time monitoring of equipment operating status and fault indication.

Operation manual / automatic two styles. With manual and automatic switching function: In the manual mode, can be stand-alone operation, easy maintenance; In automatic mode, carry out full production run, in order to start; across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operating personnel Safety.

Machinery main components of the brand:

PLC control system: Siemens

Inverter: Taiwan Shilin

Encoder: Omron

Touch screen: Siemens

Some components are Schneider brand devices.

V,Devices completed 16 fold cabinet frame prodution line

| No. | Machine name | QTY | REMARK |

| 1 | Uncoiler straightener | 1 | |

| 2 | Servo Feeder | 1 | |

| 3 | Hydraulic machine/Punch machine | 1 | With mould |

| 4 | Guide device | 1 | |

| 5 | Forming machine | 1 | |

| 6 | Roller welding | 1 | |

| 7 | Follow Shear | 1 | Including knife |

| 8 | Collect rack | 1 | |

| 9 | Control system | 1 | |

| 10 | Box bending machine | 1 | With mould |

VI, Cabinet frame machine accessories brand

| No. | Name | manufacturer |

| 1 | Motor & Reducer | Domestic brands |

| 2 | The main key bearing | Domestic brands |

| 3 | Inverter | Shilin |

| 4 | PLC Systems | Siemens |

| 5 | Low-voltage electrical | Schneider |

| 6 | Encoder | Omron |

| 7 | touch screen | Siemens |

| 8 | Hydraulic system | Domestic brands |

Botou Kefa Roll Forming Machine Co., Ltd. is a manufacturer specializing in custom cold roll forming equipment and automatic production lines. We can manufacture hundred types roll forming machines,like Door frame machine,K type long span arching roof machine,automobile profile machine,Container house series machine,Steel silo series machine,Chicken cage series machine,Fence series machine,shelf series machine,highway guardrail series machine,coil leveling machine and all kinds of construction profiles.

Botou Kefa Roll Forming Machine Co., Ltd. is a manufacturer specializing in custom cold roll forming equipment and automatic production lines. We can manufacture hundred types roll forming machines,like Door frame machine,K type long span arching roof machine,automobile profile machine,Container house series machine,Steel silo series machine,Chicken cage series machine,Fence series machine,shelf series machine,highway guardrail series machine,coil leveling machine and all kinds of construction profiles.

Engineers and technicians are rich in experience of designing,developing and manufacturing of machines to provide customers with customized designs. We pay close attention to new trend of technologies.Our products are sold to many countries and regions around the world, and we have established long-term cooperative relationships with customers.

1. Quality Control

A. Every parts of machine is examed carefully without any omit.

B. Welcome to our factory to check machine

2. Installation & Training

A. We supply video to teach buyer how to install and operate machine

B. Welcome customers come to our factory, we are glad to teach you face to face.

C. Our technicians could come to customers’ factory to install machine

3. After-sale service

A. One year warranty for parts and shipment of parts is free.

B. 24hours*365 days technical support online.

Our machines are working throughout our country and overseas.Few of our reputed clients have in fact given us their repeat orders for their production expansion.

Established in 2008 year,Kefa is a professional manufacturer specializing in the developing and manufacturing of cold roll forming machine,Silo Making Machine,Curve Profile Roll Forming Machine.

1.Construction Roll Form Machine:

Roof And Wall Panel,Floor & Roof Deck,Purlines,Elevators,Metal Building Beam,Metal Framework,Drywall Stud and Track,False Ceilings,Door & Window Frame,Door Skin,Shutter Door,C/Z/U/L Shaped Steel,Roof Flashings Roll,Arch Roof Panel,Container House

2.Automotive Roll Form Machine:

Carriage Panel,Bicycle/Motorbycle Wheel Rim,Tanker/Trailer Fender,Body Sides.

3.Agricultural Roll Form Machine:

Steel Silos,Greenhouse Pipe/Channels,Conveyor Cover,Layer Cage Frame,Vineyard Post,Corrugated Sheet Curver,

4.Industry Roll Form Machine:

Fence,Leveling/Slit & Cut to Length Line,sheet rolling bending,Cone rolling bending,Lock hoop,Pipe Arch Curve,Expansion Joint,Hand rail,Guard rail,pipe milling

5.Energy & Electricals

Solar Panels,Conduits,Light Fixtures,Pylons,Cable Trays,Cabinets,Box.

6.Logistics Roll Form Machine

Metal Containers,Upright,Shelving,Mezzanine Floors,Walkways,Scaffolding,Cold Rooms,Pallet Rack,

KEFA has been engaged in the metal roll forming industry for many years and devoted to developing some steel structure machines with a professional technology and reasonable price. In particular, we can provide professional service, high quality, through design and installation. At KEFA, our experience is our advantage.