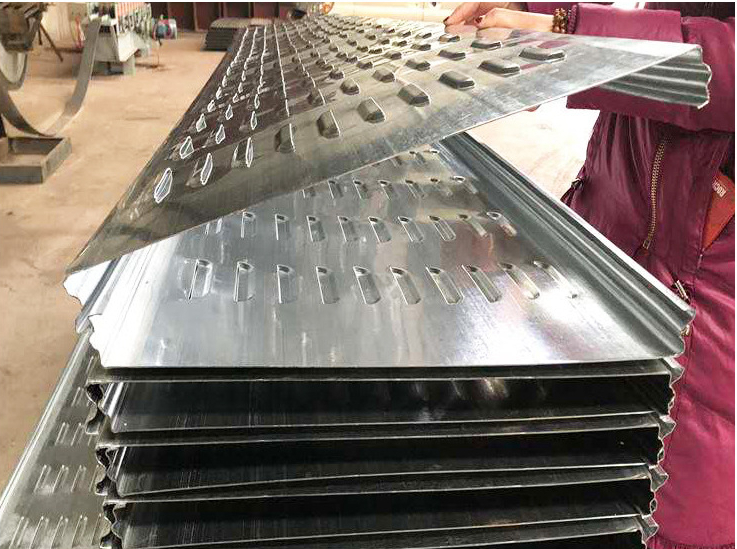

Highway Sound Barrier Box Board Forming Machine

Roll forming machine for make Highway Sound Barrier Box Board includes two steps: STEP1:making sound barrier box board STEP2: making slotted panel highway soundproof box board is any means of reducing the sound pressure with respect to a specified sound, Highway noise barrier can reduce wind, engine, road, and tire noise.

• Production working flow

1: Produce 1-rib panel, Decoiler→Forming Machine A-Hydraulic cutting-output

2: Produce 2-ribs panel, Decoiler→Forming Machine B-Hydraulic cutting→output

3: Produce C channel pad (Left & Right), Decoiler→online punch→ Forming Machine→Hydraulic cutting→output

4: after manual assembles, go through a clamping machine.

5: louver punch machine (this is an optional machine, the barrier could use a perforated panel or louver pattern panel)

Acoustic panel post roll forming machine Machine design capacity

1. Raw material thickness: 1.2mm

2. Raw material yield limit: Gl.

3. the working speed with punching: 0-10m/min

Machine components

Machine 1#:1-rib rolling forming machine

2#:2-rib rolling forming machine

3#:C channel pad punch & forming machine

4#:Clamping machine

5# louver perforated machine

Each part technical parameter

Machine 1#:1-rib rolling forming machine

1.10T Manual decoiler

2.1-rib Roll Forming Machine

Machine 2#:2-ribs rolling forming machine

1.10T Manual decoiler

2.1-rib Roll Forming Machine

Machine 3#:C channel Pad (left & right) the Machine 4#: Clamping Machine

Machine 5#: Louver Punch Machine

|

Item |

Name |

Description |

|

1 |

Decoiler |

Capacity:5 tons |

|

2 |

Material |

Steel Coil |

|

3 |

Thickness |

0.5-1.6mm |

|

4 |

Transmission |

Chain/Gear/Gearbox |

|

5 |

Speed |

10-15m/min |

|

6 |

Roller |

Steel with quenched treatment,chromed on the surface |

|

7 |

Shaft |

steel with tempering treatment |

|

8 |

Cutting type |

Hydraulic cutting |

|

9 |

Cutting material |

Cr12 with quenched treatment Hardness58°-62° |

|

10 |

Welding |

Automatic spot welding |

|

11 |

Control system |

PLC |

|

12 |

Electric brand |

Delta,Siemens,Schneide |

|

13 |

Voltage |

380V,50HZ,3PH(or as customers’ request) |